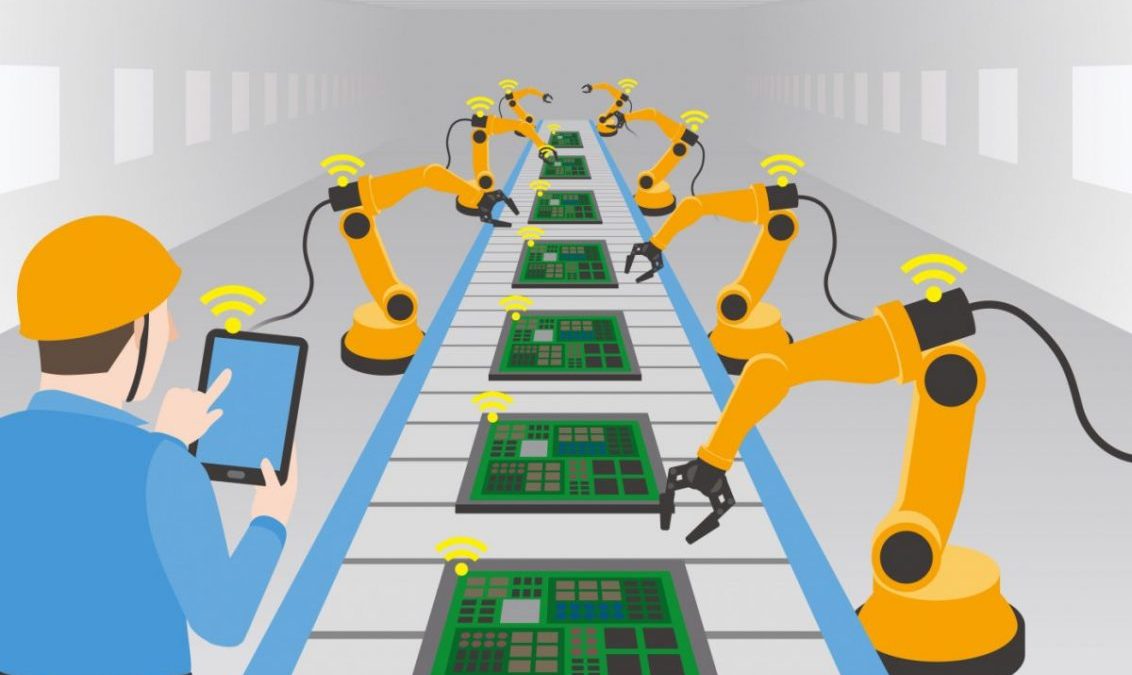

Automation is at the heart of every industry. Over the last decade, automation has become so sophisticated to the point of replacing humans that do repetitive, and risky jobs. In auto industries, assembly lines have been extensively automated for years now. Robotics has been engineered to automate processes for increased safety and productive capacity.

Ways automation is altering the manufacturing sector are multi-faceted as every manufacturing area has a tweak. Some of the alterations are discussed below:

Faster and efficient processes of doing things

Automation promises and renders increased productivity, resulting in labor cost reduction, Improved safety, optimum quality, and overall efficiency.

In manual or labor-intensive manufacturing, there are many mischanneled resources as most times, production time and energy are channeled towards correcting human errors and clunky procedures. With automation integrated into the production process, a high level of efficiency can be achieved. Manufacturers who adopt automated processes will most likely smile at the bank as this could translate to increased revenues.

Gathering data through digital twinning

Digital twinning entails virtually modeling the manufacturing process similitude with real-world systems. This gives companies an upper hand to collect valuable data and models for simulation and experimentation. There has been a trend of large manufacturers leveraging the technology, which promises to get even more complex. Twinning eventually improves production quality by 30%. It allows companies to pair data with experimentation, thereby increasing revenue yielding results.

Increased Safety

Several manufacturing roles have been replaced by Robotics in a bid to promote safety and inversely reducing accidents. Some of these roles include:

- Assembly line: Co-bots work side-by-side with humans on assembly lines to bring about a faster production process.

- Sanitation: More robots are handling janitorial services in modern workspaces. They ensure workspaces are sanitized.

- Heavy lifting: Human workers are prone to several health and safety risks following the constant movement and shuffling of parts and packaging in the manufacturing industry. With Robots, these risks can be reduced as they can efficiently move large objects across a factory.

With all these risky roles being replaced by robots, workers can now enjoy safety, and not just that, manufacturers are also safe from liability risks.

AI Enhanced logistics

Integrating AI in the manufacturing process to enhance logistics is reshaping the industry. AI relies on accumulated manufacturing data drafted from sensors, digital twinning, analytics, and more to understand better and predict factory success.

From every recurring data set, AI can better learn a system, inform technicians of when maintenance is due while building better models for an effective process.

Conclusively, this means that each new data set helps AI learn a system. Technicians are informed on maintenance, and better models can be built for an effective process.

As Automation and Artificial intelligence are increasingly integrated into the manufacturing process, we could suffice to say that efficiency can be promised with worker’s safety at the pyramid of the success ranking while boosting manufacturers’ revenues.